Recovery methods for deformed claw springs

Recovery methods for deformed claw springs

Minor Deformation Correction for Claw Springs: If a claw spring experiences slight bending or twisting, it can be straightened using professional tools or a heated rod matching its shape inside an oven for thermal straightening. However, this method entails risks, and improper handling may cause further damage or safety issues, thus it's not recommended for non-professionals.

Using Special Tools: For specific types of claw springs, like spiral compression claw springs, specific mechanical devices can sometimes restore them to their original state. These devices typically require adjustment by the manufacturer or experienced maintenance personnel within the industry to ensure safety and accuracy.

Material Inspection and Replacement: Inspecting the quality of the metal material used is crucial to prevent future deformations. Higher-quality alloy steel or other high-strength materials can enhance fatigue resistance and durability, preventing future warping or twisting. Additionally, selecting appropriate heat treatment processes can improve elastic limits and service life, reducing maintenance needs.

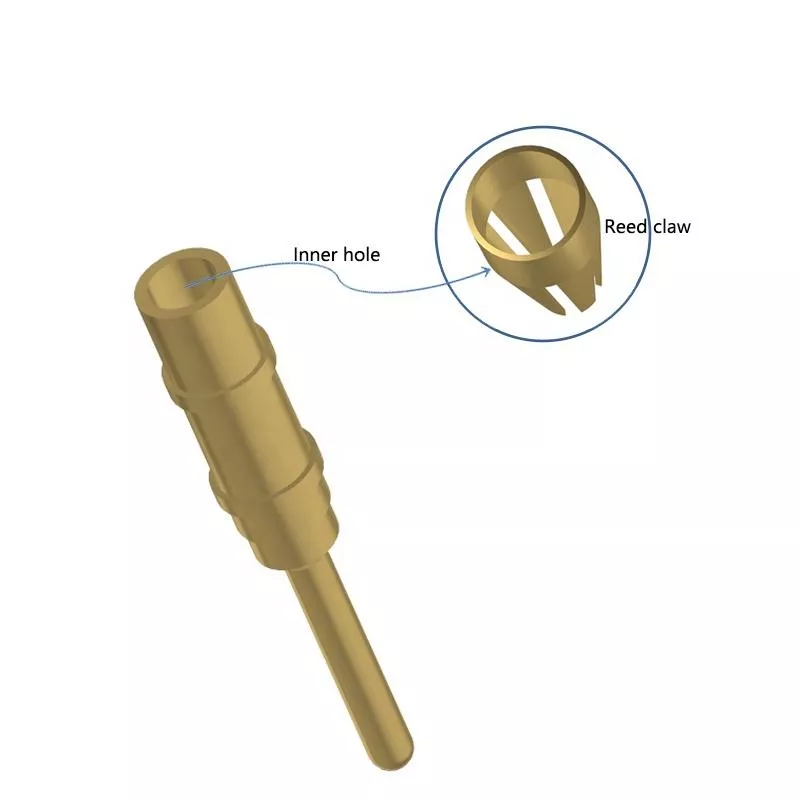

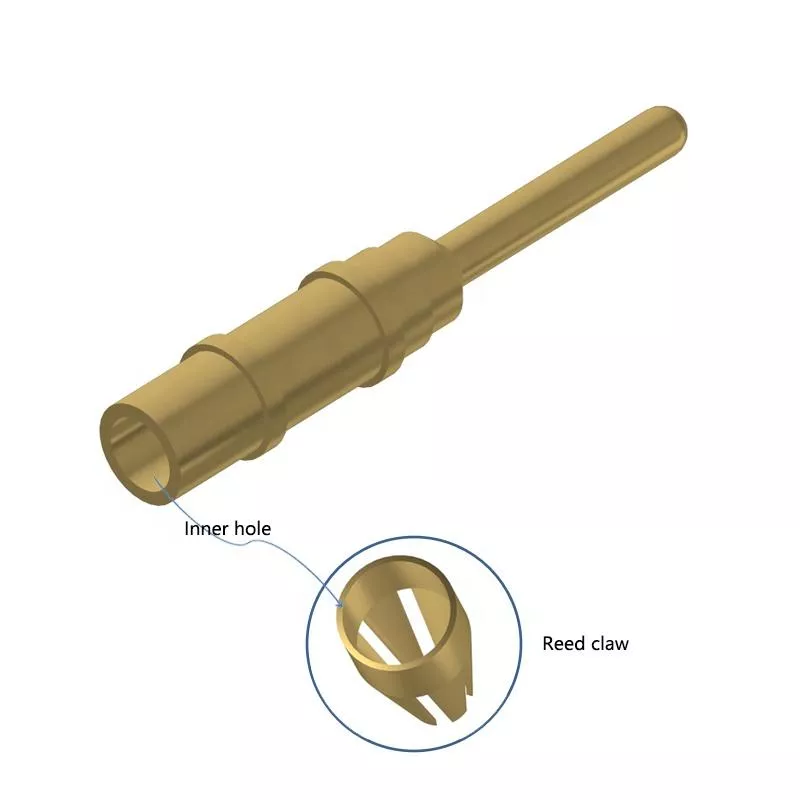

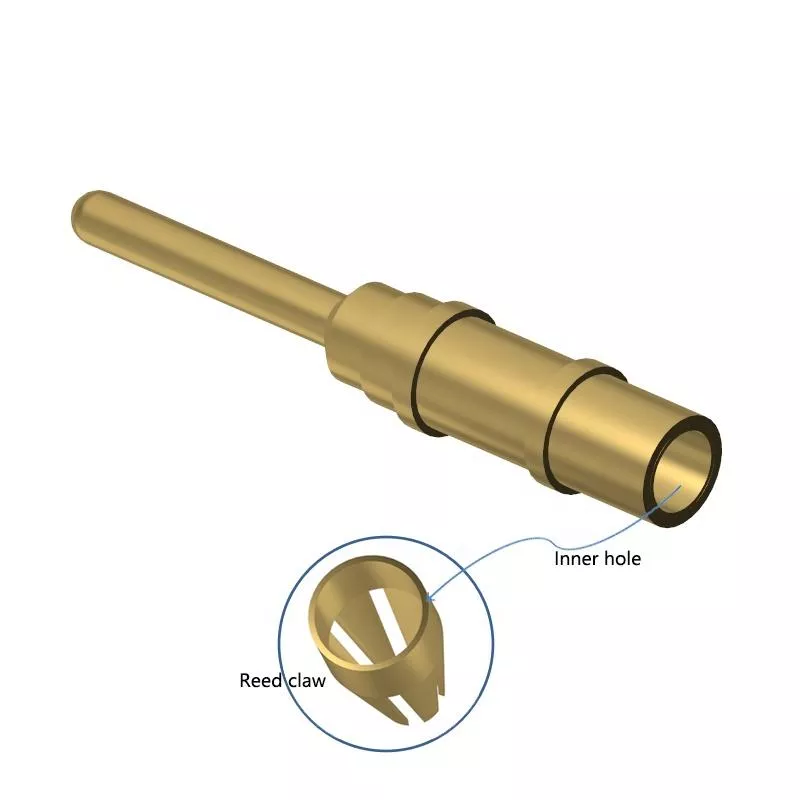

Improving Claw Spring Structure: Modifying the claw spring structure, such as adding annular protrusions on its inner side, can increase overall strength and metal fatigue resistance. This makes the claw spring less prone to plastic deformation. Even after multiple uses, the claw part of the contact component maintains its shape, providing consistent gripping force over time.