Guide for Selecting High-Current Pogopin

Guide for Selecting High-Current Pogopin

In fields such as industrial equipment, new energy vehicles, and medical instruments, high-current pogopin serves as a crucial connector component. Its selection directly impacts the performance and safety of the equipment. Below are 5 core points to help you quickly choose the right high-current pogopin:

1. Clarify Application Scenario Requirements

1. Accurate Positioning of Current Range: First, determine the actual operating current of the equipment. Common specifications of high-current pogopin cover 10A-100A, and a 20%-30% current redundancy should be reserved to avoid heat damage caused by long-term full-load operation;

2. Matching Environmental Adaptability: For outdoor, high-temperature, or humid environments, select products with an IP65 or higher waterproof rating and a temperature resistance range of -40℃ to 125℃; for medical equipment, additional attention should be paid to materials with biocompatibility.

2. Focus on Core Electrical Parameters

1. Contact Resistance: High-quality high-current pogopin should have a contact resistance of ≤20mΩ. Excessively high resistance will increase energy consumption and generate high temperatures, so you can request actual test data from the supplier;

2. Rated Voltage: Choose based on the operating voltage of the equipment. Conventional products support 5V-60V, and for high-voltage scenarios, a customized insulating structure is required to prevent breakdown and leakage;

3. Current Density: Avoid only focusing on the rated current. Instead, calculate the current density based on the cross-sectional area of the pin. Generally, it is recommended to be ≤8A/mm² to reduce the risk of local overheating.

3. Pay Attention to Structure and Material

1. Selection of Structure Type:

• Single-pin structure: Suitable for scenarios with limited space, featuring flexible installation;

• Multi-pin array: Ensure uniform pin spacing (common 2.0mm/2.54mm) to guarantee balanced current distribution;

1. Core Materials:

• Pin Shaft: Prefer brass plated with hard gold (wear-resistant and with good conductivity); beryllium copper can be used for high-demand scenarios;

• Spring: Choose stainless steel material to ensure stable elasticity after long-term compression and avoid poor contact;

• Shell: Phosphor bronze plated with nickel to enhance corrosion resistance and structural strength.

4. Attach Importance to Reliability Testing

1. Mechanical Life: It should meet at least 5,000 insertion and extraction cycles; for high-frequency use scenarios, it should be increased to more than 10,000 cycles;

2. Vibration and Shock Testing: Industrial equipment needs to pass a 10-2000Hz vibration test, and products for the automotive field need to additionally meet a shock strength of ≥500G (0.3ms);

3. Salt Spray Testing: For applications in outdoor or humid environments, the product must pass a 48-hour neutral salt spray test to ensure no rusting.

5. Screen for High-Quality Suppliers

1. Qualification Verification: Prioritize manufacturers with ISO9001 and IATF16949 certifications; for the automotive field, additionally confirm whether they have passed automotive-grade testing;

2. Customization Capability: If there are special size (such as pin length, diameter) or current requirements, confirm whether the supplier supports mold opening and customization, with a delivery cycle of ≤4 weeks.

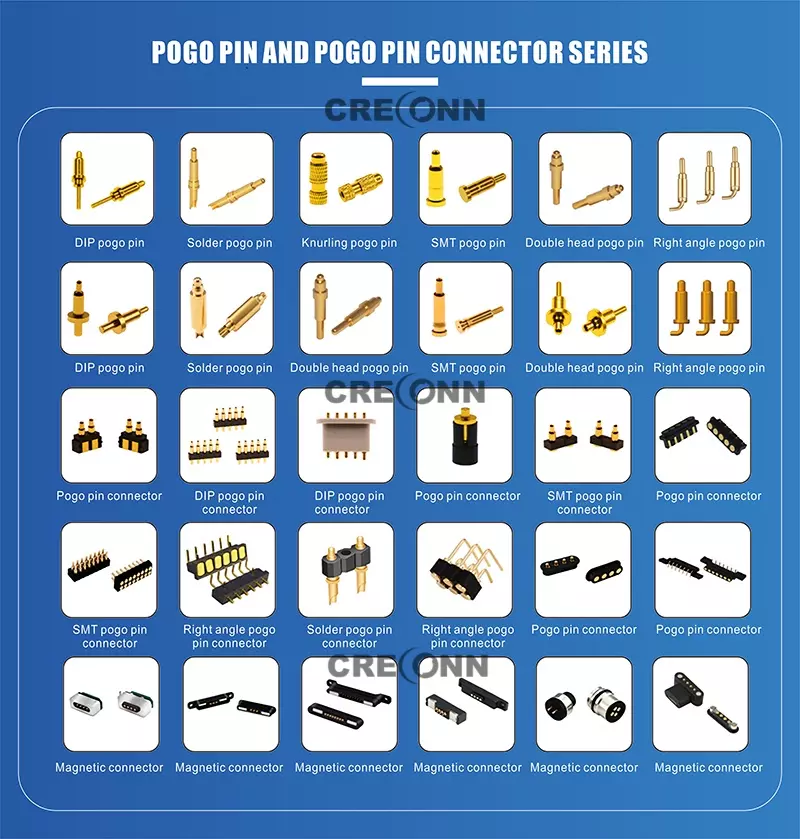

Guangdong Corecon Precision Industry Co., Ltd. has been a professional manufacturer of pins, sockets,pogo pins, pogo pin connectors and hardware CNC precision parts in China for 18 years. And we have gotten certificate of ISO9001 and IATF16949. If you have any questions about the pin and socket industry, please contact us and we will provide you with free, one-stop professional solutions within 24 hours.