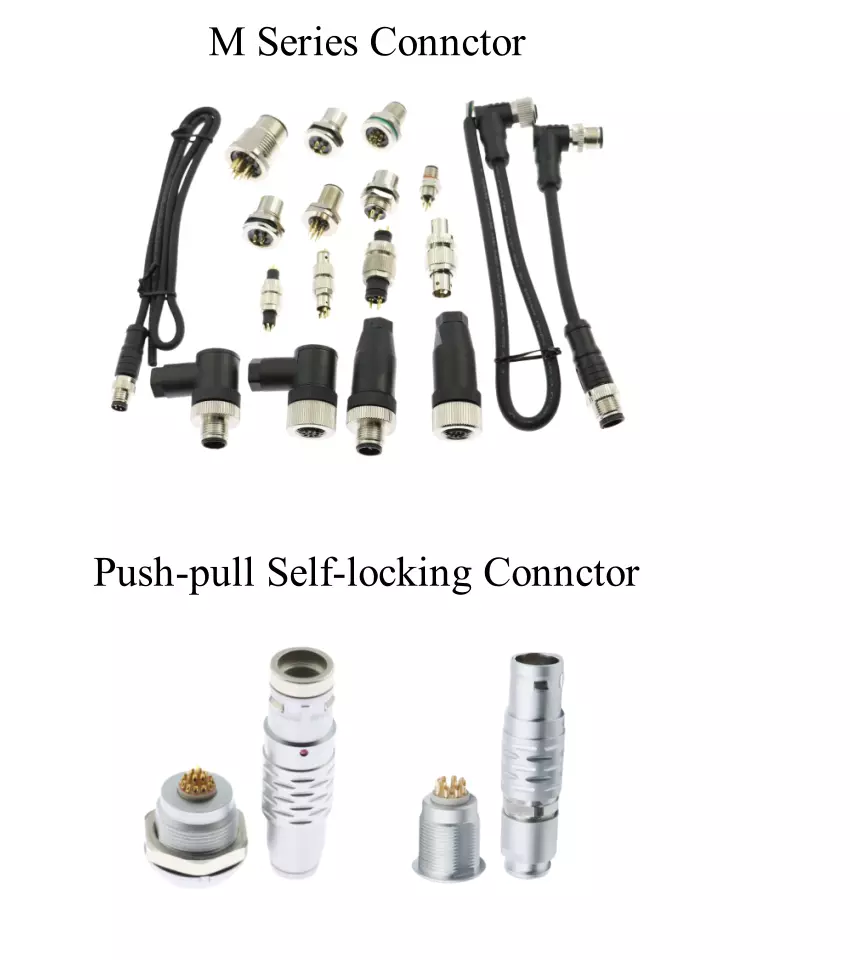

Push-Pull Self-Locking vs. M-Series Connectors: 4 Dimensions for Quick Selection

Push-Pull Self-Locking vs. M-Series Connectors: 4 Dimensions for Quick Selection

1. Comparison of Installation Convenience

◦ Push-Pull Self-Locking Connectors: Adopt a "push-pull" operation mode without rotation, enabling plugging and unplugging within 3 seconds. They operate flexibly in narrow spaces (such as dense wiring areas inside equipment) and are suitable for scenarios requiring frequent assembly and disassembly (e.g., medical testing equipment, stage lighting modules).

◦ M-Series Connectors: Mostly feature a threaded locking design, which requires 3-5 rotations to fix. They operate stably in spacious spaces but tend to have the issue of "being hard to twist" in narrow environments, making them more suitable for long-term fixed connections (e.g., fixed wiring of industrial equipment).

1. Differences in Vibration Resistance

◦ Push-Pull Self-Locking Connectors: Fixed by a latch structure, they can remain stable under normal vibration (such as slight vibration of office equipment). However, there is a risk of latch disengagement under extreme vibration (e.g., automobile engine compartments, large machine tools).

◦ M-Series Connectors: With deep thread engagement and high mechanical strength, they can withstand continuous strong vibration (vibration frequency: 50-2000Hz) and offer better reliability in high-frequency vibration scenarios such as industrial automation production lines and engineering machinery.

1. Distinctions in Sealing Performance

◦ Push-Pull Self-Locking Connectors: Mainstream products can reach an IP67 protection rating (protection against short-term immersion), and some high-end models can achieve IP68. Nevertheless, their sealing life is relatively short in environments with long-term immersion or high-pressure flushing.

◦ M-Series Connectors: Most models have a default IP67 rating, and some industrial-grade products support IP69K (protection against high-pressure and high-temperature flushing). They perform better in humid/watery scenarios such as food processing equipment (requiring frequent flushing) and outdoor water conservancy monitoring instruments.

1. Recommendations for Application Scenario Adaptation

◦ Priority for Push-Pull Self-Locking Connectors: Scenarios with frequent plugging/unplugging, limited space, and normal environments (e.g., medical equipment modules, small electronic instruments, temporary wiring for exhibitions).

◦ Priority for M-Series Connectors: Scenarios requiring long-term fixation, strong vibration resistance, and high sealing performance (e.g., industrial automation equipment, automotive electronic control systems, outdoor heavy machinery).

Guangdong Corecon Precision Industry Co., Ltd. specializes in various industrial connector, push-pull self-locking connectors, new energy connectors, M series connectors , waterproof connectors, electric bicycle signal and power connector, and all kinds of wire harnesses. If you have any questions related to the connector industry, please contact us and we will provide you with free, one-stop professional solutions within 24 hours.